The Front horizontal Rail is used in conjunction with a puller for the installation of PCB boards, rails, and panel fixation.

Prevents Module Sag: Eliminates front-end droop in fully loaded subracks

Improves Connector Alignment: Ensures perfect mating of module connectors

Easy Retrofit: Installs easily on existing front horizontal rails

Industrial Grade: Withstands vibration and shock in harsh environments

Product Name: Rugged Long Lip - Front Rail Reinforcement Bracket

Core Function: Specifically engineered reinforcement component that mounts to the front horizontal rail of electronic subracks to prevent module sagging and maintain precise alignment under heavy loads.

Detailed Description:

The Rugged Long Lip solves a critical problem in high-density electronic systems: front-end module sagging. When subracks are fully populated with heavy modules, the front horizontal rail can deflect, causing misalignment, poor connector engagement, and potential system failures. This reinforcement bracket adds crucial structural support to the front rail, maintaining perfect module alignment and ensuring reliable performance in demanding applications from industrial automation to telecommunications.

Technical Specifications

| Parameter | Specification |

|---|---|

| Application | Front Horizontal Rail Reinforcement |

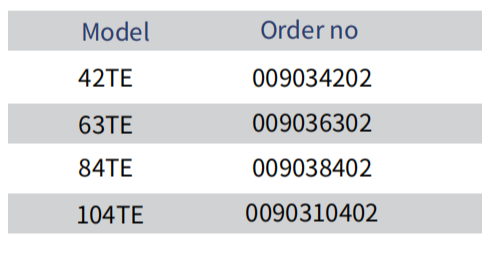

| Compatible Systems | Standard 19" subracks (EG Series, BEK/BEG, etc.) |

| Material | High-Strength Aluminum Alloy |

| Surface Finish | Black Anodized (Corrosion Resistant) |

| Load Capacity | Increases front rail stiffness by 40%* |

| Installation | Tool-less snap-on design |

Problem & Solution Section

The Problem: Front Rail Flex

Modules sag under their own weight

Connectors misalign, causing intermittent contacts

System reliability compromised in vibration environments

Difficult maintenance access due to binding modules

The Solution: Rugged Long Lip

Adds reinforced ledge support along entire front rail

Maintains module alignment within 0.5mm tolerance

Distributes load evenly across rail structure

Compatible with existing module designs

Installation Benefits

Quick Installation: Snap-on design requires no tools or modifications

No Re-engineering: Works with your current modules and subracks

Immediate Improvement: Enhanced stability from first installation

Maintenance Friendly: Easy removal for subrack service access

Application Scenarios

Telecom Base Stations: Prevents module sag in vibrating environments

Military Systems: Maintains alignment under shock and vibration

Industrial Controls: Ensures reliable operation in manufacturing plants

Test & Measurement: Protects expensive instrumentation modules

RESOURCES

Catalog

![]() BEK&BEG PRO Series Subracks.pdf

BEK&BEG PRO Series Subracks.pdf

Contact Us

Whether you’d like to get more info on what, why and how we do what we do, need help with what you’re creating, would like to partner up or just say hi!---we’d love to hear from you.